Consulting phone:

135-3037-2041

(Mr.Wang)

Product introduction:

The super lithium ion capacitor comprises a housing, a super lithium capacitor arranged between the upper and lower internal surfaces of the housing and a charging control circuit. The upper and lower internal surfaces of the housing are respectively provided with wireless receiving coils for receiving wireless charging signals. The current generated by the wireless receiving coils charges the super lithium capacitor through the charging control circuit.

The main parameters

serial number | characteristic | Numerical value |

1 | Rated Capacity | 2200mAh+5% |

2 | upper limit voltage | 4.2V |

3 | Lower limit voltage | 2.5V |

4 | DC internal resistance (10ms) | ≤11mΩ |

5 | Standard charging current | 6.6A (3C) |

6 | Fast charge current | 22A(10C) |

7 | Rated discharge current | 22A(10C) |

8 | Continuous discharge current | 60A(30C) |

9 | Discharge duration | 100s |

10 | temperature rise | 55± 5℃ |

11 | safety | Refer to GB/T 31485-2015 "Safety Requirements and Test Methods for Power Batteries for Electric Vehicles" |

12 | Charge and discharge temperature range | -40~85℃ |

13 | Storage temperature range | -40~55℃ |

14 | Fast charge cycle life (@25 ± 2 ℃) | ≥30,000 times (10C) |

15 | Slow charge cycle life | ≥50,000 times (1C) |

16 | weight | ≤65g |

17 | Dimensions (diameter D × height H) | Φ21mm ×70mm |

Product test method:

The standard test conditions are: under standard atmospheric pressure, the temperature is 25 ± 2 ℃, and the relative humidity is less than 65%.

Capacity/internal resistance test

Capacity test: under the condition of 25 ± 5 ℃, charge the product at 1C to the set voltage of 4.2V, then charge at constant voltage to 0.1C, and then discharge the product at 1C to 2.5V. After standing for 30s, repeat the above process again, and take the capacity value (mAh) after the second discharge as the capacity value of the product.

Internal resistance test: charge the product to 4.2V with 3C current, and read its AC internal resistance (ACR) on the 1kHz AC impedance meter after the stabilized voltage charge to 0.1C cut-off current. When measuring the capacity of the product, it is necessary to record the voltage difference of the sample within 10ms from the start of the discharge to the discharge during the discharge process= Δ U/I Calculate the DC internal resistance (DCR) of the product. Note: During the "capacity and internal resistance" test, the recording time of the data acquisition point is set as 1s.

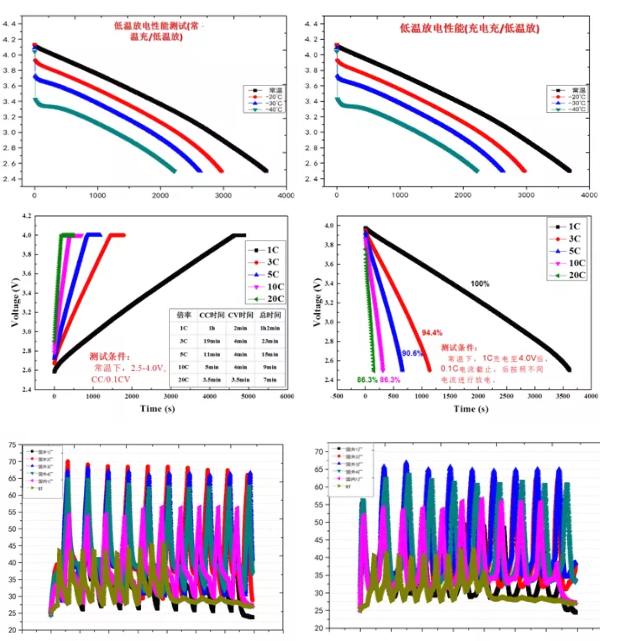

Low temperature performance test

Under the condition of setting temperature, charge the unit to 4.2V and then charge it to 0.1C at constant voltage to cut off. Under different temperature conditions, discharge the unit to 2.5V at 1C current, and record the capacity of the unit during discharge.

Other technical information

Product testing method:

The standard test conditions are: standard atmospheric pressure, temperature 25±2℃, relative humidity less than 65%.

Capacity/Internal Resistance Test

Capacity test: under the condition of 25±5℃, charge the product at 1C to the set voltage of 4.2V, then charge the product with constant voltage to 0.1C, and then discharge the product to 2.5V at 1C current. After standing for 30s, repeat the above process again, and take the capacity value (mAh) after the second discharge as the capacity value of the product.

Internal resistance test: charge the product to 4.2V with a 3C current, and then charge the product to a 0.1C cut-off current, then read its AC internal resistance (ACR) on a 1kHz AC impedance meter. When measuring the capacity of the product, it is necessary to record the voltage difference of the sample from the start of discharge to the discharge within 10ms during the discharge process, and calculate the DC internal resistance (DCR) of the product by R=ΔU/I. Note: During the "capacity and internal resistance" test, the recording time of the data collection point is set to 1s

Low temperature performance test

Under the set temperature condition, charge the cell to 4.2V, then charge it with constant voltage to 0.1C, then put it under different temperature conditions, discharge the cell to 2.5V with a current of 1C, and record the capacity of the cell during the discharge process.

Cycle life

Under the condition of 25±5℃, after the initial performance is measured according to the "capacity/internal resistance test" method, the product is charged to 4.0V with a current of 5C, discharged to 2.5V with a constant current of 2C and left for 5min, and the cycle test After 2000 weeks. The above test process is a cycle, and the test process needs to repeat the above cycle 15 times, and finally achieve 30,000 life tests.

Precautions:

Ⅰ. Use

1. Lithium Ion Capacitors The operating temperature should not exceed the upper or lower limit of the rated temperature (-20 degrees ~ +55 degrees)

2. Lithium ion capacitor Should be used at nominal voltage. At the same time, in order to prolong the service life of the product, it is recommended that the monomer be used in " Rated voltage "(2.5v-3.8v) range.

3. Please confirm the polarity of lithium-ion capacitors before use, and avoid reverse connection.

4. The external ambient temperature has a heavy impact on the life of lithium-ion capacitors, please keep away from heat sources.

5. Do not directly touch water, oil, acid or alkali for lithium ion capacitors.

6. Do not knead, nail, or disassemble Li-ion capacitors.

7. Do not discard lithium-ion capacitors at will. When discarding, please dispose of them in accordance with national environmental protection standards.

Ⅱ. Storage

1. During the transportation of lithium-ion capacitors, avoid violent vibration, kneading, rain and chemical corrosion, and handle with care.

2. Lithium-ion capacitors should not be placed in places with a relative humidity of more than 85% or containing toxic gases. In such an environment, the leads and casings are susceptible to moisture and corrosion, resulting in an open circuit of the ultra-fast rechargeable battery.

3. If the lithium-ion capacitor needs to be stored for a long time, please store it in a place with a temperature of -40~35 degrees, a relative humidity below 50%, and good ventilation