Consulting phone:

135-3037-2041

(Mr.Wang)

Product introduction:

Lithium ion fast charging capacitor is also known as the energy storage principle of ultrafast charging battery, which belongs to the category of ultrahigh power lithium ion battery. Its central idea is to combine the characteristics of physical energy storage and chemical energy storage to solve the bottleneck problem of existing lithium ion batteries. The dual track energy storage mechanism is formed through the internal fusion of super capacitor and lithium ion battery. With the help of super capacitor ultra-high power manufacturing technology, the pain point problem of existing lithium ion battery is solved.

Product specification:

| Serial No | characteristic | numerical value | numerical value | numerical value |

| 1 | Rated capacity | 1500mAh+5% | 1300mAh+5% | 1100mAh+5% |

| 3150F+5% | 2750F+5% | 2100F+5% | ||

| 2 | Upper limit voltage | 4.2V | 4.2V | 4.2V |

| 3 | Lower limit voltage | 2.5V | 2.5V | 2.5V |

| 4 | DC internal resistance (10ms) | ≤11mΩ | ≤13mΩ | ≤15mΩ |

| 5 | Standard charging current | 4.5A(3C) | 3.9A(3C) | 3.9A(3C) |

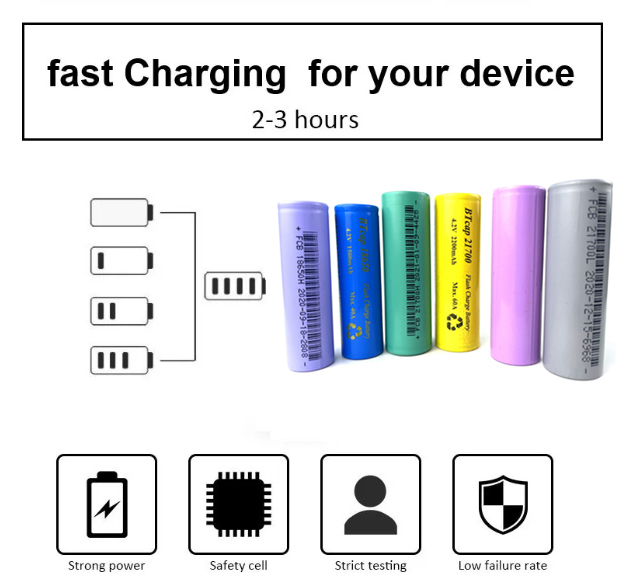

| 6 | Fast charging current | 15A(10C) | 13A(10C) | 11A(10C) |

| 7 | Rated discharge current | 4.5A(3C) | 3.9A(3C) | 3.3A(3C) |

| 8 | Continuous discharge current | 45A(30C) | 39A(30C) | 33A(30C) |

| 9 | Discharge duration | 200s | 200s | 200s |

| 10 | temperature rise | 55±5℃ | 55±5℃ | 55±5℃ |

| 11 | Security | Refer to GB/T 31485-2015 Safety Requirements and Test Methods of Power Storage Capacitors for Electric Vehicles | Refer to GB/T 31485-2015 Safety Requirements and Test Methods of Power Storage Capacitors for Electric Vehicles | Refer to GB/T 31485-2015 Safety Requirements and Test Methods of Power Storage Capacitors for Electric Vehicles twelve |

| 12 | Charging and discharging temperature range | -40~85℃ | -40~85℃ | -40~85℃ |

| 13 | Storage temperature range | -40~55℃ | -40~55℃ | -40~55℃ |

| 14 | Fast charging cycle life (@ 25 ± 2 ℃) | ≥ 30000 times (10C) | ≥ 30000 times (10C) | ≥ 30000 times (10C) |

| 15 | Slow charging cycle life | ≥ 50000 times (1C) | ≥ 50000 times (1C) | ≥ 50000 times (1C) |

| 16 | weight | ≤45g | ≤45g | ≤45g |

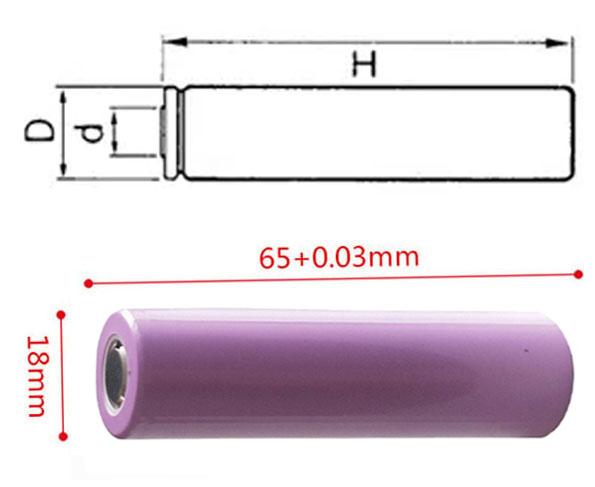

| 17 | Dimension (diameter D × Height H) | Φ 18mm × 65mm | Φ 18mm × 65mm | Φ 18mm × 65mm |

Product size:

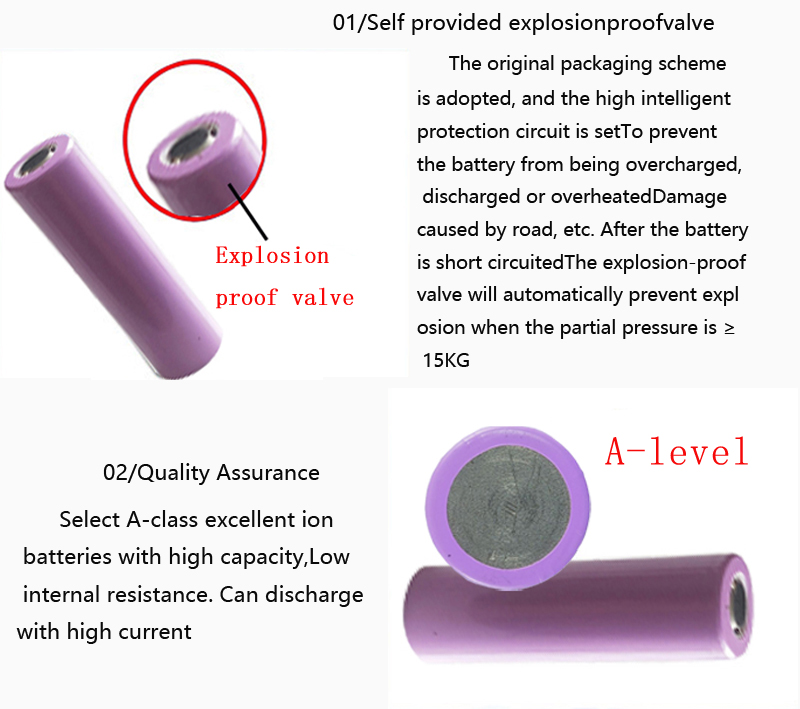

Product advantages:

Product advantages:

First, high power density=instantaneous release of high power. Unlike batteries, supercapacitors can release large power instantaneously to ensure that the blades can quickly return to the neutral position in case of grid failure. Since the charging speed of supercapacitors is much faster than that of batteries, supercapacitors can also provide high reliability in the case of short-term mismatch between power demand and power supply capacity.

Second, reduce the total acquisition cost. The initial investment cost of the electric pitch system using super capacitors is the same as that of the battery system, but the electric pitch system using batteries (excluding energy storage devices) requires more complex charging and monitoring systems, which leads to higher costs. The system using super capacitor requires fewer components, and the mechanism of mechanical installation and vibration reduction is simpler than the battery system.

Third, it has a long service life and predictable aging cycle. The average life of supercapacitors under normal working conditions is 12 years, which is mainly attributed to two factors: first, supercapacitors can work in a wide temperature range from - 40 ℃ to 65 ℃; Second, it can reliably operate for 500000 to 1 million cycles of charging and discharging. Different from supercapacitors, the operating temperature range of the battery is narrow, and the battery will be severely damaged by harsh environmental conditions and continuous charging and discharging. The battery needs to be replaced every two to four years.

Fourth, there is no heating and cooling cost. Batteries are susceptible to extreme temperatures, while supercapacitors are fine. The battery needs to be heated and cooled. Therefore, the design cost of battery system is bound to be higher, and supercapacitor does not need such additional high maintenance cost.

Fifth, it is light in weight. The battery energy storage system usually has to adopt a super large design to meet the peak power requirements. The system using batteries is relatively larger and bulkier. The super capacitor is much lighter, because it can release large power instantly, which can fully meet the peak power demand, so it does not need to adopt super large design.

Widely used:

The 18650 lithium ion capacitor can be used in energy storage devices for new energy generation, wind power generation and photovoltaic power generation. It can buffer energy in the case of uneven wind power to achieve stable energy storage. It can also be used as the power supply of the fan pitch system for civil and rapid charging and discharging, with long life cycle, no manual maintenance, wide temperature tolerance range, etc.

Lithium ion capacitor

Technical advantages and product characteristics of lithium ion electrical appliances (ultra fast charging batteries) (cylindrical products)

1. Material formula of high power composite electrode: the world's original high power composite material and its electrode manufacturing technology enable the battery to achieve high specific energy while ensuring high power. Realizing the combination of super capacitor and lithium battery in a real sense.

2. Long life electrolyte matching technology: we specially develop special electrolyte for high-power batteries. With the advantages of high conductivity and high temperature stability, it is the "lubricating oil" in super batteries.

3. Structural design of high power energy storage battery: For the first time, the full pole lug diversion structure was adopted in the structural design of 18650 cylindrical battery. It reduces the internal resistance of the battery itself, and solves the electrical connection problem of the battery in the process of high power charge/discharge from the perspective of cell assembly. The self power consumption of the battery is reduced while the energy utilization efficiency is improved.

Advantages of lithium ion appliances (super fast charging battery):

1. Safety: reliable energy storage principle; Design overcharge and overvoltage protection; Material safety, not easy to explode and fire

2. Suitable temperature: rechargeable at minus 40 °; Dischargeable at 85 ℃ at high temperature; Application - 40 ° - 85 °

3. High magnification: continuous charging 15C; Continuous discharge 30C; Instantaneous discharge 50C;

4. Ultra long life: physical energy storage; Cycle life ≥ 5000 times; 100% DOD; Service life: 10 years

Lithium ion capacitor

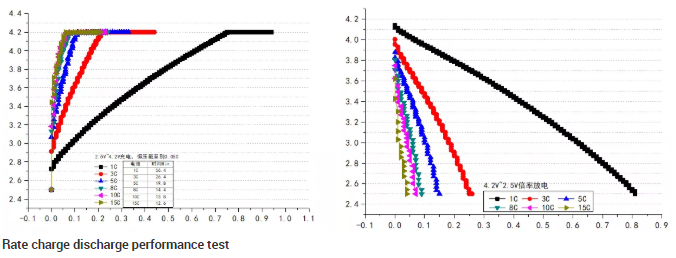

Product test method

1. Test conditions

The standard test conditions in the product specification are: under standard atmospheric pressure, the temperature is 25 ± 2 ℃, and the relative humidity is less than 65%.

2. Capacity/internal resistance test

Capacity test: under the condition of 25 ± 5 ℃, charge the product at 1C to the set voltage of 4.2V, then charge at constant voltage to 0.1C, and then discharge the product at 1C to 2.5V. After standing for 30s, repeat the above process again, and take the capacity value (mAh) after the second discharge as the capacity value of the product.

Internal resistance test: charge the product to 4.2V with 3C current, and read its AC internal resistance (ACR) on the 1kHz AC impedance meter after the stabilized voltage charge to 0.1C cut-off current. When measuring the capacity of the product, it is necessary to record the voltage difference of the sample within 10ms from the start of the discharge to the discharge during the discharge process= Δ U/I Calculate the DC internal resistance (DCR) of the product. Note: During the "capacity and internal resistance" test, the recording time of the data acquisition point is set as 1s.

3. Low temperature performance test

Under the condition of setting temperature, charge the unit to 4.2V and then charge it to 0.1C at constant voltage to cut off. Under different temperature conditions, discharge the unit to 2.5V at 1C current, and record the capacity of the unit during discharge.

4. Cycle life

Under the condition of 25 ± 5 ℃, after the initial performance is tested according to the method of "capacity/internal resistance test", the product is charged to 4.0V with 5C current, discharged to 2.5V with 2C current constant current, and left for 5min. After 2000 weeks of cycling test. The above test process is a cycle. The test process needs to repeat the above 15 cycles to achieve 30000 life tests.

matters needing attention:

use

V The service temperature of ultra fast charging lithium ion capacitor should not exceed the upper or lower limit of rated temperature.

V Ultra fast charging lithium ion capacitor shall be used under rated voltage range.

V Please confirm the polarity of ultra fast charging lithium ion capacitor before use, and reverse connection is prohibited.

V The ambient temperature has an important influence on the life of the ultrafast lithium ion capacitor. Please stay away from the heat source.

V Do not directly contact water, oil, acid or alkali with the ultra fast charging lithium ion capacitor.

V Do not squeeze, puncture or disassemble the ultrafast lithium ion capacitor.

V Do not discard the ultrafast rechargeable lithium ion capacitor at will, and dispose it according to the national environmental protection standards.

V This product has a certain voltage value before delivery, so do not short-circuit the positive and negative terminals during use.

Storage

V The ultra fast charging lithium ion capacitor shall not be located in a place with a relative humidity of more than 85% or containing toxic gas. In such an environment, the lead and shell are prone to moisture and corrosion, which may lead to the open circuit of the lithium ion capacitor.

V If the ultrafast charging lithium ion capacitor needs to be stored for a long time, please store it in a well ventilated place with a temperature of - 20~55 ℃ and a relative humidity below 60%. It is strictly prohibited to expose to the sun.