Consulting phone:

135-3037-2041

(Mr.Wang)

Product introduction

Lithium ion capacitor module is a hybrid electrochemical energy storage device, which combines the embedding mechanism of lithium ion battery anode and the double-layer mechanism of double-layer capacitor (EDLC) cathode. The combination of negative battery type LTO electrode and positive capacitor type activated carbon (AC) results in an energy density of about. 20Wh/kg, about 4-5 times of the standard double-layer capacitor (EDLC). However, the power density has been proved to match the EDLC because it can discharge completely in a few seconds. On the negative electrode (anode) where activated carbon is often used, the charge is stored in the double electric layer formed at the interface between the electrode and the electrolyte. Like EDLC, the voltage of LIC varies linearly, which increases the complexity of integrating them into the system, which has power electronic devices that expect more stable battery voltage. Therefore, LICs have a high energy density, which varies with the square of the voltage. The capacitance of the anode is several orders of magnitude larger than that of the cathode. Therefore, the change of anode potential during charging and discharging is far less than that of cathode potential.

Product specification:

| project | characteristic |

| Rated voltage | 24V or customized |

| Capacity | 1.9AH or customized |

| Working temperature | - 40 ℃ - 65 ℃ |

| Tolerance | 0+20% |

| Size | 9.5*6.5*5cm |

| Line length | 11cm |

| weight | 0.64kg |

| Temperature characteristics | from - 40 ℃ to 65 ℃ Capacity change: △ c ∠ 30% of initial measured value @ 25 ℃ Internal resistance change: △ ESR ∠ 100% of nominal value |

| Under high temperature load life of | 25 ℃ and rated voltage, load 1000h capacity change: △ c ∠ 30% of initial measured value @ 25 ℃ internal resistance change: △ ESR ∠ 200% of nominal value |

| Under normal temperature load life of | 25 ℃ and rated voltage, load capacity change in 10 years: △ c ∠ 30% of initial measured value @ 25 ℃ internal resistance change: △ ESR ∠ 200% of nominal value |

| Under normal temperature cycle life of | 25 ℃, after 500000 charge-discharge cycles (from rated voltage to 1/2 rated voltage), capacity change: △ c ∠ 30% of initial measured value @ 25 ℃ internal resistance change: △ ESR ∠ 200% of nominal value |

Main features of module

◎ Long life, hundreds of thousands of times of charging;

◎ The charging speed is fast, and it only takes 0.3 seconds to 15 minutes to charge;

◎ High charge-discharge efficiency up to 98%;

◎ High power density

◎ Wide operating temperature range, which can be used in the temperature range of - 40 ℃~+65 ℃;

◎ Good ultra-low temperature characteristics can work in the environment of minus 40 ℃;

◎ Completely maintenance-free;

◎ No pollution to the environment, green environmental protection;

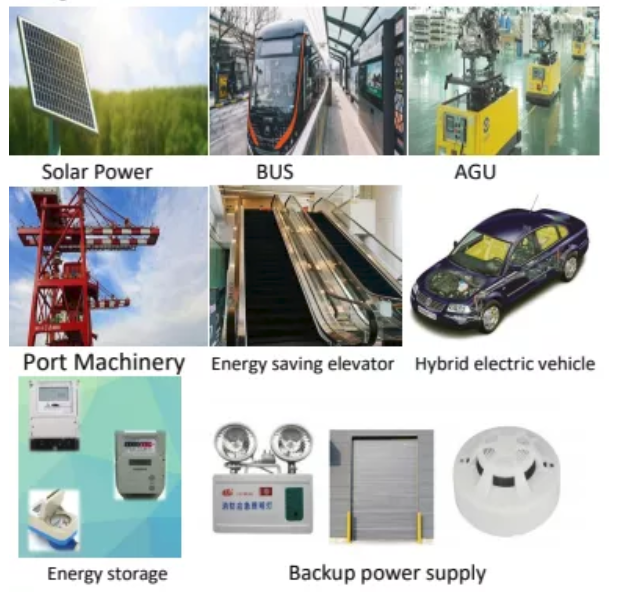

Product application:

Fast charging application, charging in seconds and discharging in minutes. For example, electric tools and electric toys; For elevators, unmanned aerial vehicles, electric forklifts and tour buses, in the UPS system, supercapacitors provide instantaneous power output as a supplement to the standby power supply of engines or other uninterruptible systems; Apply to energy with sufficient energy and insufficient power, such as solar energy; Power support when the bus switches from one power source to another; Small current, long-term continuous discharge, such as computer memory backup power supply.

Test method:

The standard test conditions are: under standard atmospheric pressure, the temperature is 25 ± 2 ℃, and the relative humidity is less than 65%.

Capacity/internal resistance test

Capacity test: under the condition of 25 ± 5 ℃, charge the product at 1C to the set voltage of 4.2V, then charge it at constant voltage to the current of 0.1C, and then discharge the product at 1C current to 2.5V. After standing for 30s, repeat the above process again, and take the capacity value (mAh) after the second discharge as the product capacity value.

Internal resistance test: charge the product to 4.2V with 3C current, stabilize the charge to 0.1C cut-off current, and then read its AC internal resistance (ACR) on a 1kHz AC impedance meter. When measuring the capacity of the product, it is necessary to record the voltage difference of the sample within 10ms from the beginning of discharge to discharge during the discharge process= Δ U/I calculates the DC internal resistance (DCR) of the product. Note: During the "capacity and internal resistance" test, the recording time of the data acquisition point is set to 1s.

Low temperature performance test

Under the set temperature condition, charge the monomer to 4.2V and then charge it at constant voltage to 0.1C to stop. Put it into different temperature conditions, discharge the monomer to 2.5V with 1C current, and record the capacity of the monomer discharge process.

cycle life

At 25 ± 5 ℃, after the initial performance is measured according to the "capacity/internal resistance test" method, the product is charged to 4.0V with a current of 5C, and discharged to 2.5V with a constant current of 2C, and left standing for 5min. After 2000 weeks of cyclic test. The above test process is a cycle, and the test process needs to repeat the above 15 cycles to finally achieve 30000 life tests.

matters needing attention:

1、 Application

1. The operating temperature of lithium-ion capacitor should not exceed the upper or lower limit of rated temperature (- 20 ℃~+55 ℃)

2. Lithium ion capacitor shall be used at nominal voltage. Together, in order to extend the service life of the product, the monomer is recommended to be used within the range of "rated voltage" (2.5v-3.8v).

3. Before using the lithium-ion capacitor, please acknowledge the polarity and prevent reverse connection.

4. The ambient temperature has a weight effect on the life of lithium-ion capacitor. Please keep away from heat sources.

5. Do not touch water, oil, acid or alkali directly.

6. Do not knead, prick or disassemble the lithium-ion capacitor.

7. Do not discard the lithium-ion capacitor at will. Please dispose it according to the national environmental protection standards.

2、 Storage

1. During the transportation of lithium-ion capacitors, the products should be kept away from violent vibration, kneading, rain and chemical corrosion, and should be handled with care.

2. Li-ion capacitors cannot be placed in places with a relative humidity of more than 85% or containing toxic gases. In such an environment, the lead and shell are susceptible to moisture and corrosion, resulting in an open circuit of the ultra-fast charging battery.

3. If lithium-ion capacitors need to be stored for a long time, please store them in a well-ventilated place with a temperature of - 40~35 ℃ and a relative humidity of less than 50%.