Consulting phone:

135-3037-2041

(Mr.Wang)

Product introduction:

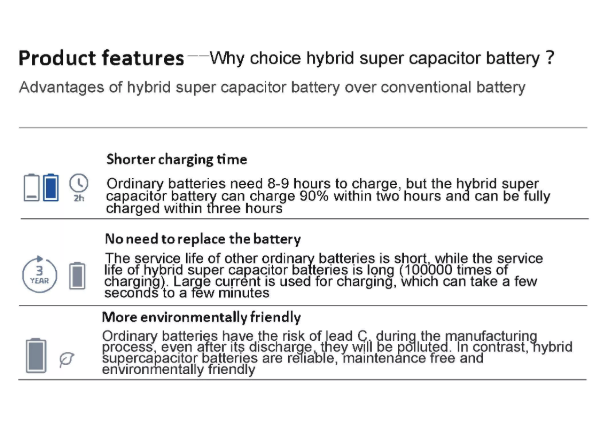

Yukunyuan gold capacitor (Farad capacitor, supercapacitor) is a capacitor made by using the principle of inductive double charge layer formed between the active carbon of electronic conductor and the organic or inorganic electrolyte of ionic conductor. It has the characteristics of small size, large capacity, good voltage memory characteristics, and high reliability. Because of its large capacity, it can store more charges, so it can be used in electronic products, industrial control equipment Backup power supply and auxiliary power supply are used in some products in automobile industry and other fields. Compared with rechargeable batteries, supercapacitors have the advantages of short charging time, high power density, long service life, good low-temperature characteristics and no environmental pollution. Therefore, supercapacitors can replace rechargeable batteries in many fields, and show the characteristics of surpassing rechargeable batteries in some aspects, making up for the shortcomings of rechargeable batteries in use, such as slow charging, complex charging circuit, short service life and other defects. Supercapacitor is an ideal environment-friendly physical secondary power supply that can provide powerful pulse power.

Product specification:

| project | characteristic |

| Rated voltage | 3.0V |

| Capacity | 3.3F |

| Working temperature | - 40 ℃ - 65 ℃ |

| Tolerance | 0+30% |

| Temperature characteristics | from - 40 ℃ to 65 ℃ Capacity change: △ c ∠ 30% of initial measured value @ 25 ℃ Internal resistance change: △ ESR ∠ 100% of nominal value |

| Under high temperature load life of | 25 ℃ and rated voltage, load 1000h capacity change: △ c ∠ 30% of initial measured value @ 25 ℃ internal resistance change: △ ESR ∠ 200% of nominal value |

| Under normal temperature load life of | 25 ℃ and rated voltage, load capacity change in 10 years: △ c ∠ 30% of initial measured value @ 25 ℃ internal resistance change: △ ESR ∠ 200% of nominal value |

| Under normal temperature cycle life of | 25 ℃, after 500000 charge-discharge cycles (from rated voltage to 1/2 rated voltage), capacity change: △ c ∠ 30% of initial measured value @ 25 ℃ internal resistance change: △ ESR ∠ 200% of nominal value |

Product performance table:

| Model | voltage V | capacity F | AC internal resistance m Ω 1KHz | 24h leakage current uA | Product size mm | ||

| Diameter D | length H | foot distance P | |||||

| YKY08123R0E105HPJ | 3.0 | 1 | 300 | 10 | 8 | 12 | 3.5 |

| YKY08203R0E335HPJ | 3.0 | 3.3 | 140 | 33 | 8 | 20 | 3.5 |

| YKY10203R0E505HPJ | 3.0 | 5 | 90 | 50 | 10 | 20 | 3.5 |

| YKY13203R0E106HPJ | 3.0 | 10 | 60 | 100 | 13 | 20 | 5 |

| YKY16253R0E256HPJ | 3.0 | 25 | 30 | 250 | 16 | 25 | 7.5 |

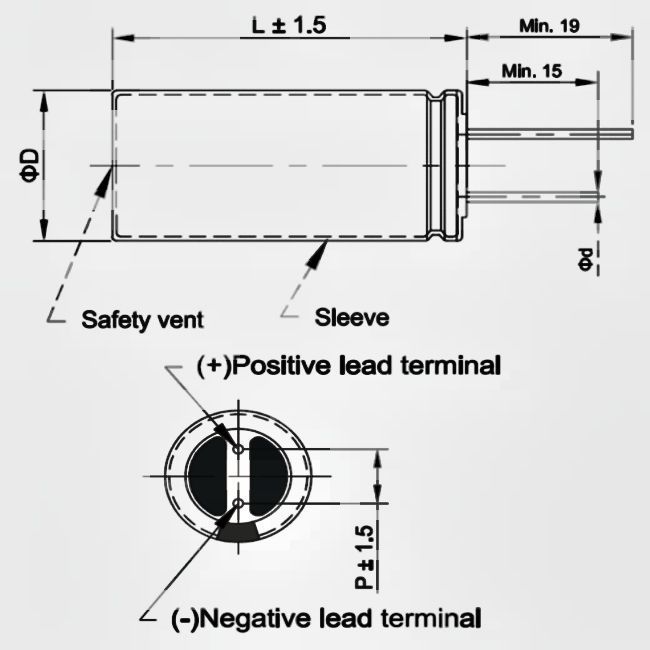

Dimensions (unit: mm)

Product display:

Product packaging:

Product advantages:

Application areas:

![1669272893126405.png [~]P`CO9T}7YQI[(0(}~%%E.png](http://en.szsyky.cn/data/upload/202211/1669272893126405.png)

testing method:

1. Electrostatic capacity test method:

(1) Test principle

The test of the electrostatic capacity of the supercapacitor is to use the method of constant current discharge of the capacitor, and calculate it according to the formula.

C=It(U1-U2)

In the formula: C - electrostatic capacity, F;

I-constant discharge current, A;

U1, U2 - use voltage, V;

t-Discharge time required for U1 to U2, S

(2), test procedure

Charge the capacitor with a current of 100A, charge the capacitor to the working voltage and keep the voltage constant for 10 seconds, then discharge the capacitor with a current of 100A, take U1 as 1.2V and U2 as 1.0V, record the discharge time within this voltage range, and the total cycle Capacitance, take the average value.

2. Stored energy test

(1) Test principle:

The test of supercapacitor energy is carried out by the method of discharging the capacitor with constant power to 1/2 of the working voltage with a given voltage range of the capacitor. The output energy W of the capacitor is obtained from the relationship between the constant discharge power P and the discharge time T, namely:

W=PT

(2) Test procedure

Charge the capacitor to the working voltage with a constant current of 100A, and then keep it constant until the charging current drops to the specified current (10A for traction type, 1A for start-up type), after 5 seconds of rest, discharge the capacitor with constant power to 1/2 of the working voltage, record Discharge time and calculate magnitude. Repeat the measurement 3 times and take the average value.

3. Equivalent series resistance test (DC)

(1) Test principle

The internal resistance of the capacitor is measured according to the sudden change of the voltage within 10 milliseconds of the capacitor disconnecting the constant current charging circuit. That is: in the formula:

R - the internal resistance of the capacitor;

U0 - capacitor cut off the voltage before charging;

Ui - cut off the voltage within 10ms after charging;

I - cut off the current before charging.

(2) Measurement process

Charge the capacitor with a constant current of 100A, disconnect the charging circuit when the charging working voltage is 80%, use a sampling machine to record the voltage change value within 10 milliseconds after the capacitor is powered off, and calculate the internal resistance, repeat 3 times, and take the average value.

4. Leakage current test

After charging the capacitor to the rated voltage with a constant current of 100A, charge the capacitor with a constant voltage for 30min at this voltage value, and then leave it open for 72h. During the first three hours, the voltage value was recorded every minute, and during the remaining time, the voltage value was recorded every ten minutes.

Calculate the self-discharge energy loss, SDLF=1-(V/VW)2, and the calculation time points are: 0.5, 1, 8, 24, 36, 72h.

Note: The voltage tester must have high input impedance to minimize the impact of discharge.