Consulting phone:

135-3037-2041

(Mr.Wang)

Product introduction:

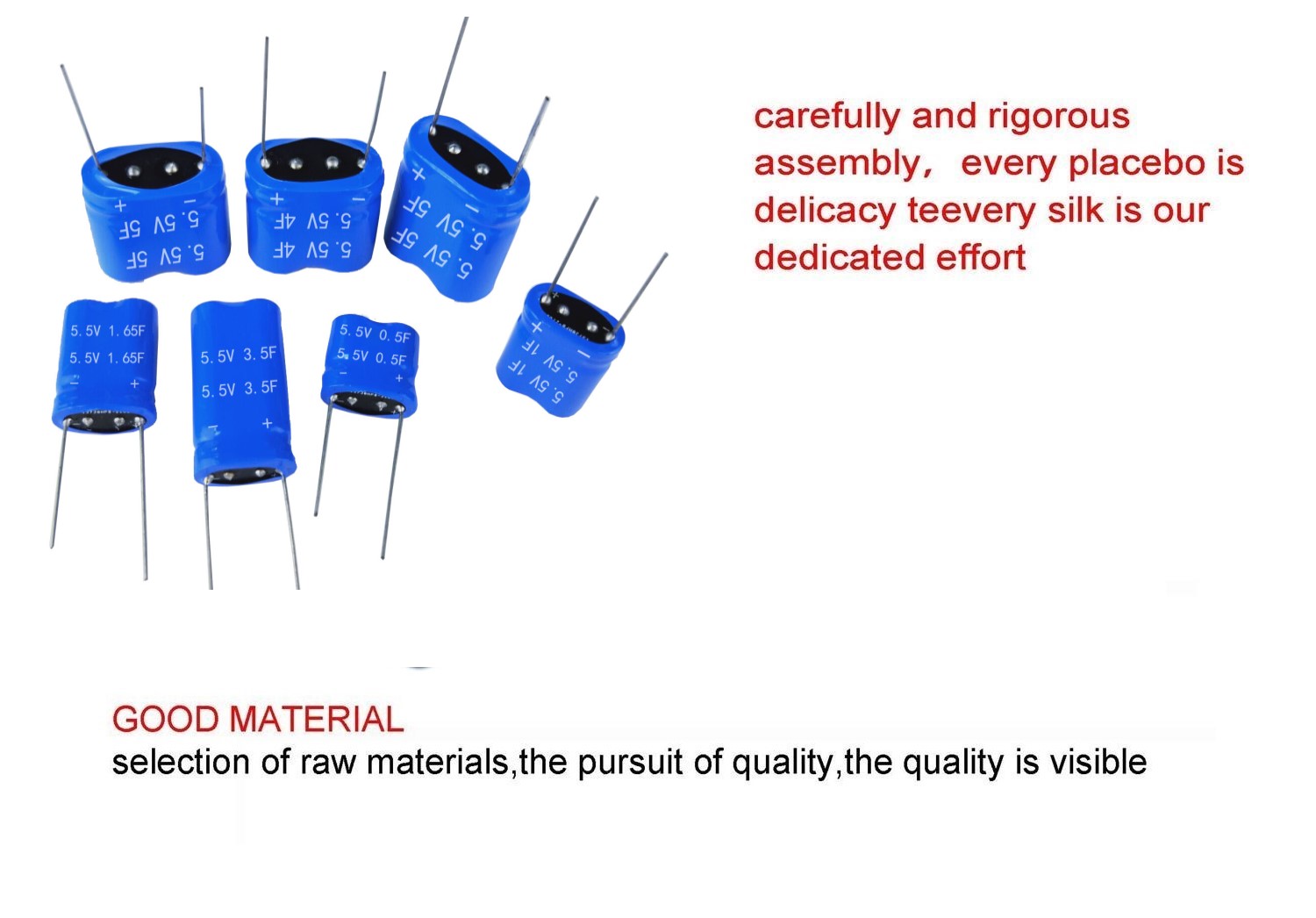

Supercapacitor is a new type of energy storage device between traditional capacitors and rechargeable batteries. It not only has the characteristics of rapid charging and discharging of capacitors, but also has the energy storage characteristics of batteries. Imported ACP activated carbon is used as electrode and organic electrolyte. Operating temperature range: - 40 ℃~+65 ℃, cycle life:>500000 times, environmental protection, small internal resistance, large capacity, small leakage current, long service life, high reliability and good product consistency It can charge and discharge quickly, providing high power output for equipment

Series Specification Sheet

Specification | characteristic | ||||||

5.5V.DC | |||||||

surge voltage | 5.7V.DC | ||||||

Capacity range | 0.47 | ||||||

Operating temperature range | -40℃~+65℃ | ||||||

Product life | Normal temperature cycle life: at 25 ℃, with a constant current capacitor Cycle charge and discharge for 1 million times between the specification voltage and half rated voltage, the capacity decay is ≤30%, and the internal resistance change is ≤2 times | ||||||

High temperature endurance life: under the condition of +65℃, the rated voltage is applied for 1000 hours. Capacity attenuation ≤ 30%, internal resistance change ≤ 2 times. | |||||||

Product performance table

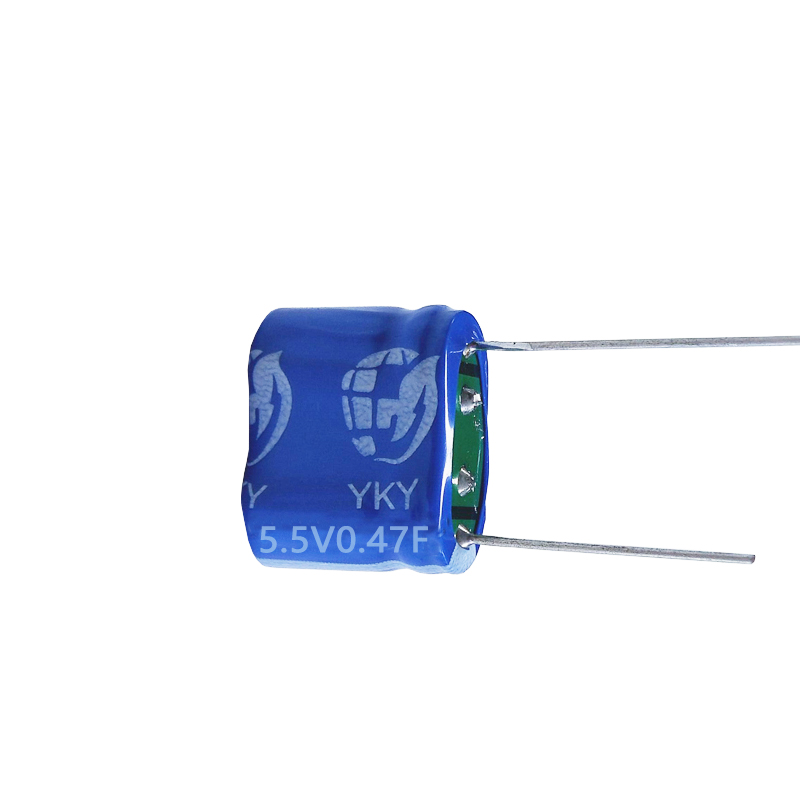

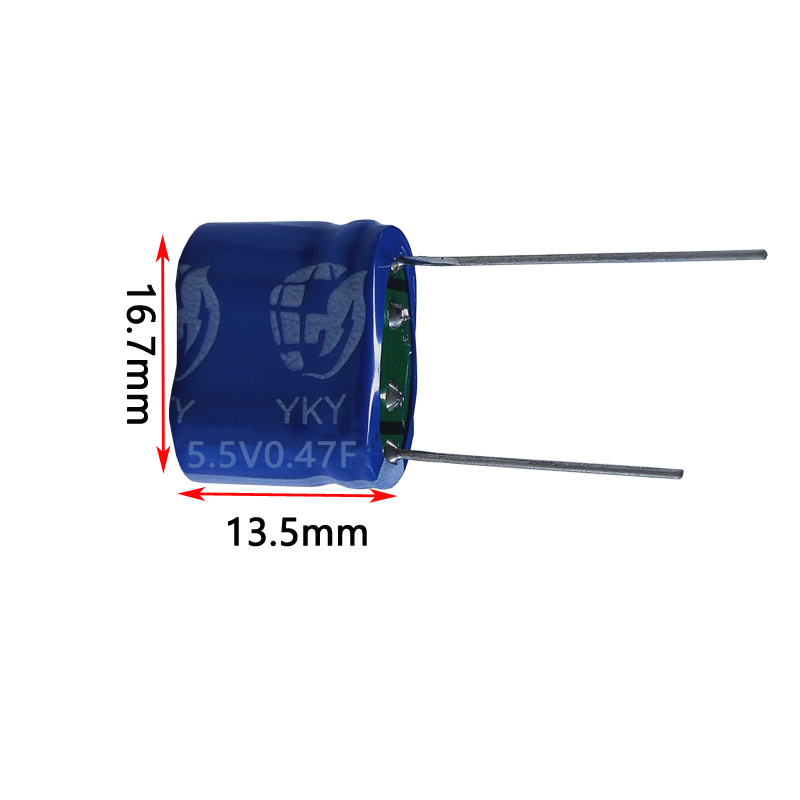

YKY05R5S0R47DARZA0Bmodel | Voltage V | Capacity F | Product size mm | AC internal resistance ESRA C(1KHz/Mω) | Working current (A) | Peak current (A) | Leakage (72hrs/mA) | ||

length W | width D | height L | |||||||

YKY05R5S0R47DARZA01 | 5.5 | 0.47 | 16.7 | 8.3 | 13.5 | 500 | 0.18 | 0.61 | 3 |

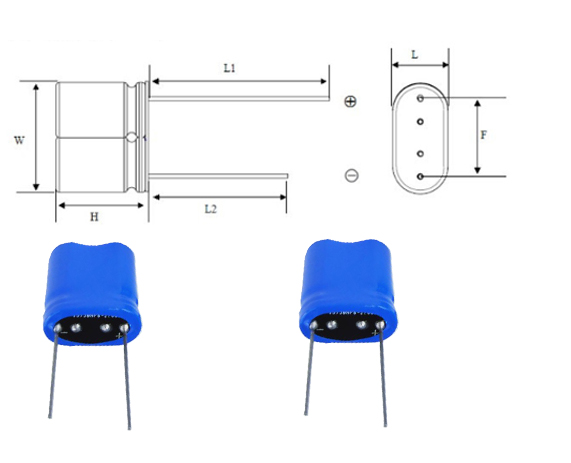

Product size:

Purpose/Application:

●Instruments such as smart electricity meters, smart water meters, and smart flow meters

●Backup power supply: RAM, detonator, car recorder , Smart Meter , vacuum switch , digital camera , motor drive EVD, computer, car navigator, digital camera

●Energy storage: Smart three watch , UPS, security equipment, communication equipment, flashlights, water meters, gas meters, tail lights, small household appliances, electric toys, cordless telephones, TV sets, rice cookers

●High current work: electrified railway, smart grid control, hybrid vehicle, wireless transmission

●High power support: wind power, Locomotive start , ignition, electric vehicle LED flash, solar power generation, etc.

testing method:

1. Electrostatic capacity test method:

(1) Test principle

Super capacitor The electrostatic capacity is tested by the method of constant current discharge of the capacitor, and it is calculated according to the formula.

C=It(U1-U2)

In the formula: C - electrostatic capacity, F;

I-constant discharge current, A;

U1, U2 - use voltage, V;

t-Discharge time required for U1 to U2, S

(2), test procedure

Charge the capacitor with a current of 100A, charge the capacitor to the working voltage and keep the voltage constant for 10 seconds, then discharge the capacitor with a current of 100A, take U1 as 1.2V and U2 as 1.0V, record the discharge time within this voltage range, and the total cycle Capacitance, take the average value.

2. Stored energy test

(1) Test principle:

The test of supercapacitor energy is carried out by the method of discharging the capacitor with constant power to 1/2 of the working voltage with the given voltage range of the capacitor. The output energy W of the capacitor is obtained from the relationship between the constant discharge power P and the discharge time T, namely:

W=P.T

(2) Test procedure

Charge the capacitor to the working voltage with a constant current of 100A, and then keep it constant until the charging current drops to the specified current (10A for traction type, 1A for start-up type), after 5 seconds of rest, discharge the capacitor with constant power to 1/2 of the working voltage, record Discharge time and calculate magnitude. Repeat the measurement 3 times and take the average value.

3. Equivalent series resistance test (DC)

(1) Test principle

The internal resistance of the capacitor is measured according to the sudden change of the voltage within 10 milliseconds of the capacitor disconnecting the constant current charging circuit. That is: in the formula:

R - the internal resistance of the capacitor;

U0 - capacitor cut off the voltage before charging;

Ui - cut off the voltage within 10ms after charging;

I - cut off the current before charging.

(2) Measurement process

Charge the capacitor with a constant current of 100A, disconnect the charging circuit when the charging working voltage is 80%, use a sampling machine, record the voltage change value within 10 milliseconds after the capacitor is powered off, and calculate the internal resistance, repeat 3 times, and take the average value.

4. Leakage current test

After charging the capacitor to the rated voltage with a constant current of 100A, charge the capacitor with a constant voltage for 30min at this voltage value, and then leave it open for 72h. During the first three hours, the voltage value was recorded every minute, and during the remaining time, the voltage value was recorded every ten minutes.

Calculate the self-discharge energy loss, SDLF=1-(V/VW)2, and the calculation time points are: 0.5, 1, 8, 24, 36, 72h.

Note: The voltage tester must have high input impedance to minimize the impact of discharge.

Usage:![1703126648968362.png [~]P`CO9T}7YQI[(0(}~%%E.png](/data/upload/202312/1703126648968362.png)

Supercapacitors cannot be used in the following states:

1) Temperatures above the nominal temperature

When the capacitor temperature exceeds the nominal temperature, the electrolyte will be decomposed, and the capacitor will heat up and the capacity will decrease.

In addition, the internal resistance increases and the service life is shortened.

2) Voltage exceeding the rated voltage

When the capacitor voltage exceeds the nominal voltage, the electrolyte will be decomposed, and the capacitor will heat up and the capacity will decrease.

In addition, the internal resistance increases and the service life is shortened. Therefore, reducing the operating voltage can improve the service life.

3) Loading of reverse voltage or AC voltage

1. The effect of ambient temperature on supercapacitors

The service life of supercapacitors is affected by the operating temperature. In general, if the operating temperature is increased by 10°C, the service life of supercapacitors will be shortened by half. Please try to use it in a low temperature environment lower than the high temperature. If it is used beyond the operating temperature, it may cause rapid deterioration of characteristics and damage.

The use temperature of supercapacitors should not only confirm the surrounding temperature and internal temperature of the device, but also the radiation heat from the heating element (power transistor, resistor, etc.) in the device, and the self-heating temperature caused by the ripple current. Also, do not install the heating element near the supercapacitor.

2. Please use the capacitor according to the positive and negative signs of the capacitor.

3. Please avoid using super capacitors in the following environments.

a) An environment that is directly splashed with water, salt water and oil, or an environment that is in a condensation state and is full of gaseous oil or salt.

b) An environment full of harmful gases (hydrogen sulfide, sulfurous acid, chlorine, ammonia, bromine, methyl bromide, etc.).

c) Environment splashed with acidic and alkaline solvents.

d) Direct sunlight or dusty environment.

e) environments subject to excessive vibration and shock.

4. Avoid overheating the capacitor during the soldering process (1.6mm printed circuit board should be 260°C during soldering, and the time should not exceed 5s).

5. Please avoid circuit wiring between the supercapacitor leads or between the solder joints of the connection board.

6. When using over-voltage or exceeding the operating temperature range beyond the rated conditions, it may cause the pressure valve to act, and the electrolyte will be ejected. Therefore, use a design approach that takes into account the possibility of this anomaly.

7. When charging and discharging rapidly, a voltage drop (also called IR drop) caused by internal impedance occurs at the beginning of charging and at the beginning of discharge. Therefore, please adopt a design method that takes into account the range of voltage variation.

8. Power-type large-capacity products (products above 10F) if the terminals are short-circuited in the charging state, there will be hundreds of amps of current flowing, which is dangerous. Please do not install or remove it while charging.

9. Do not put the capacitor into the dissolved solder, only stick the solder on the lead pins of the capacitor. Do not allow the welding rod to touch the capacitor heat shrink tube.

10. After installation, do not forcibly twist or tilt the capacitor.

11. When the supercapacitors are used in series, there is a problem of voltage balance between the cells.